Case Study: Southwest Airlines

Case Study: Southwest Airlines: An Industry Leader Takes Z-Tech HVLS Fans to the Extreme

Creating a comfortable working environment for employees is vital to ensuring operational excellence in the precision-driven aviation industry. Southwest Airlines, a renowned industry leader, recognized the need to address environmental challenges faced by their workforce and made the strategic decision to embrace HVLS (High-Volume, Low-Speed) fans as a game-changing solution.

When the Southwest team was investigating HVLS fan solutions for their Nashville, Tennessee cargo facility, VividAir’s Z-Tech HVLS fan was compared alongside its competitors. The extreme performance characteristics of the VividAir fan, as well as the industry-leading customer service provided by the VividAir team, led to the successful installation of multiple Z-Tech fans in Nashville with immediately positive employee feedback.

Well-known for their employee-first corporate culture, the Southwest team looked to replicate the success of their Nashville facility, and over the last decade has installed dozens more Z-Tech HVLS fans in more than 30 Southwest Airlines facilities across the United States. The air scientists at VividAir have partnered with Southwest to identify the unique needs of each facility, plan and execute each project on time and on budget, and deliver innovative solutions that improve air circulation, reduce humidity, and increase employee comfort.

Providing a Single Point of Contact from Project Beginning to End

The partnership between Southwest Airlines and VividAir began with a single facility, and has grown to over 20 US states over the last decade. Throughout this tremendous growth, the Southwest team has been provided a single point of contact to access the full services of the VividAir team, from initial site surveys to warranty repairs. As a full-service provider, VividAir builds, ships, installs, and services each of our products, and provides application-specific expertise throughout the purchase journey to support our customer’s goals. For Southwest, this created a seamless implementation experience from beginning to end.

From their initial contact with our team, Southwest received personal service from a VividAir HVLS fan expert who visited and surveyed each potential site, developed thorough and accurate facility layout diagrams, and presented timely and transparent quotes for management review. Upon approval, our team created a detailed project plan schedule and worked collaboratively to meet or exceed installation deadline expectations for every project. At each step, the full service and expertise of the team of VividAir air scientists stood behind our company partnership, and immediately offered assistance as needed.

Developing Innovative and Effective Solutions for Challenging Environments

High air turnover cargo facilities.

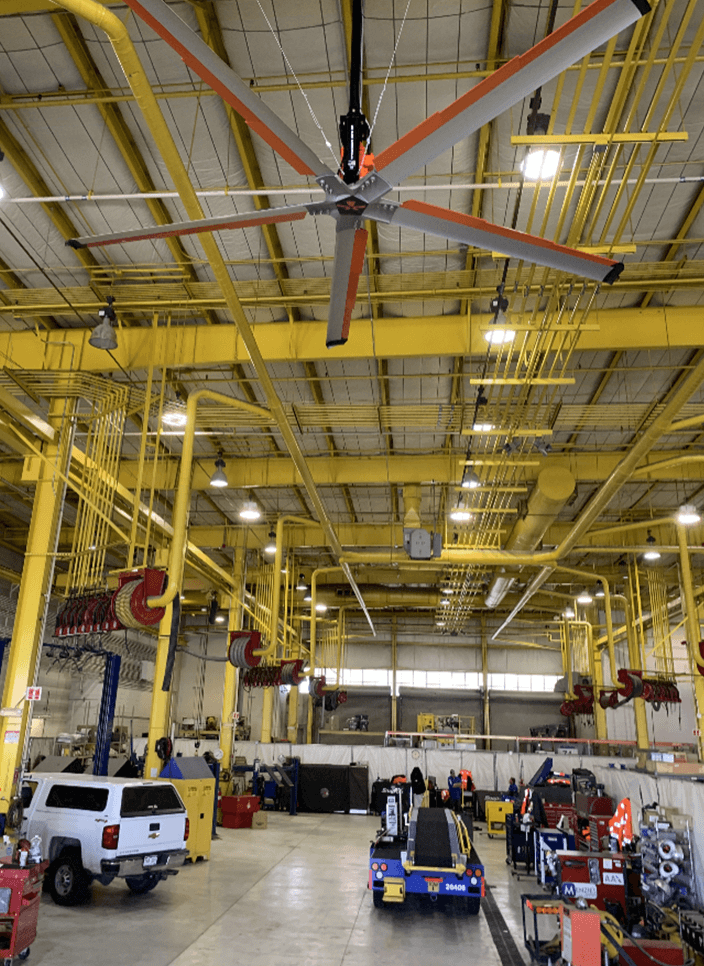

Throughout their decade-long partnership, Southwest and VividAir have worked together to identify the unique characteristics and needs of multiple different types of Southwest facilities. The initial Z-Tech fan installations in Southwest cargo facilities identified employee comfort and improved air movement as top project outcomes. With 20-foot ceilings in a high air turnover environment that includes frequent movements in and out, this type of facility presented a challenge for even the most effective air movement equipment.

But with an industry-leading coverage area that’s 30% greater than the competition and a patented blade design that eliminates “dead zones,” VividAir’s 12-foot Z-Tech HVLS fans were able to exceed both employee and management expectations.

Provisioning and maintenance facilities.

After their initial success, our Z-Tech fans were tasked with improving employee comfort, mitigating humidity and condensation, and destratifying air temperatures in Southwest’s provisioning and maintenance facilities. Built to protect food and drinks, the provisioning facilities were sensitive to both the extreme temperatures and extreme humidity present in some facility locations. Southwest’s maintenance facilities required a comfortable temperature environment for technicians to do their best work, especially when that work was extremely detailed.

The 12- and 18-foot Z-Tech HVLS fans were able to be strategically positioned and installed for maximum benefit in both facilities. Despite challenging installation conditions, the expert VividAir installation team succeeded in improving cooling comfort and condensation abatement in both types of Southwest facilities across multiple climates.

Extreme ceiling height hangar facilities.

Confident with the continued success of VividAir’s product offerings, the Southwest team challenged our Z-Tech fans with their loftiest mission yet. Southwest’s hangar facilities boast extreme 40- to 50-foot ceilings, presenting both an installation and an operational challenge. With carefully calculated placements and an expert installation crew, VividAir’s industry-leading Z-Tech fans exceeded expectations in these challenging spaces.

Southwest’s hangars are high-tech, showpiece facilities and when new locations were being constructed, VividAir’s Z-Tech fans were built into building specifications based on their prior successes. Working directly with the onsite contractors, the VividAir installation team directed the placement of multiple HVLS fans controlling distinct environments in different parts of the hangar building, each tied into the building’s automated system controls.

Coordinating Seamless Professional Installation across the United States

The VividAir installation team received rave reviews on their professionalism and expertise across multiple extreme installation environments. Our two company representatives provided a consistent and seamless installation experience for each of the Southwest facilities. With a committed core team, VividAir was able to deliver extraordinary results on schedule.

Supporting Continued Company Growth with Exceptional Customer Service

VividAir’s continued partnership with Southwest Airlines supports the company’s continuous growth, both through existing product support as well as with new product installations. VividAir backs our products with a class-leading warranty, and with US-based manufacturing and customer service, any issues can be resolved quickly with minimal business impact.

Southwest Airlines exemplified its commitment to finding sustainable solutions by adopting VividAir’s innovative HVLS fan technology to enhance employee comfort and optimize facility performance.